Pellentesque habitant morbi tristique senectus et netus pellentesque neolitics

Pellentesque habitant morbi tristique senectus et netus pellentesque neolitics

Empowering local industries, fostering innovation, creating jobs, and driving economic growth: We wholeheartedly support Make in India initiative.

Supporting indigenous products strengthens communities, economies, and cultures – be vocal for local and promote grassroots innovation.

Kamtronnix Automation: Setting the Standard in Special Purpose Machines across India. From custom solutions to cutting-edge technology, we engineer excellence for every industry need.

From assembly to quality control, Kamtronix SPMs optimize efficiency and elevate productivity across sectors. Trusted for their reliability and excellence, Kamtronix is the go-to partner for businesses seeking cutting-edge automation solutions in India.

Multiple drilling system can be attached to any vertical drilling machine and can be used for variable drill sizes custom made as per drawing.

Kamtronix Automation emerges as a beacon of innovation and efficiency, spearheading the manufacturing landscape in India with their state-of-the-art Multiple Drilling Systems.

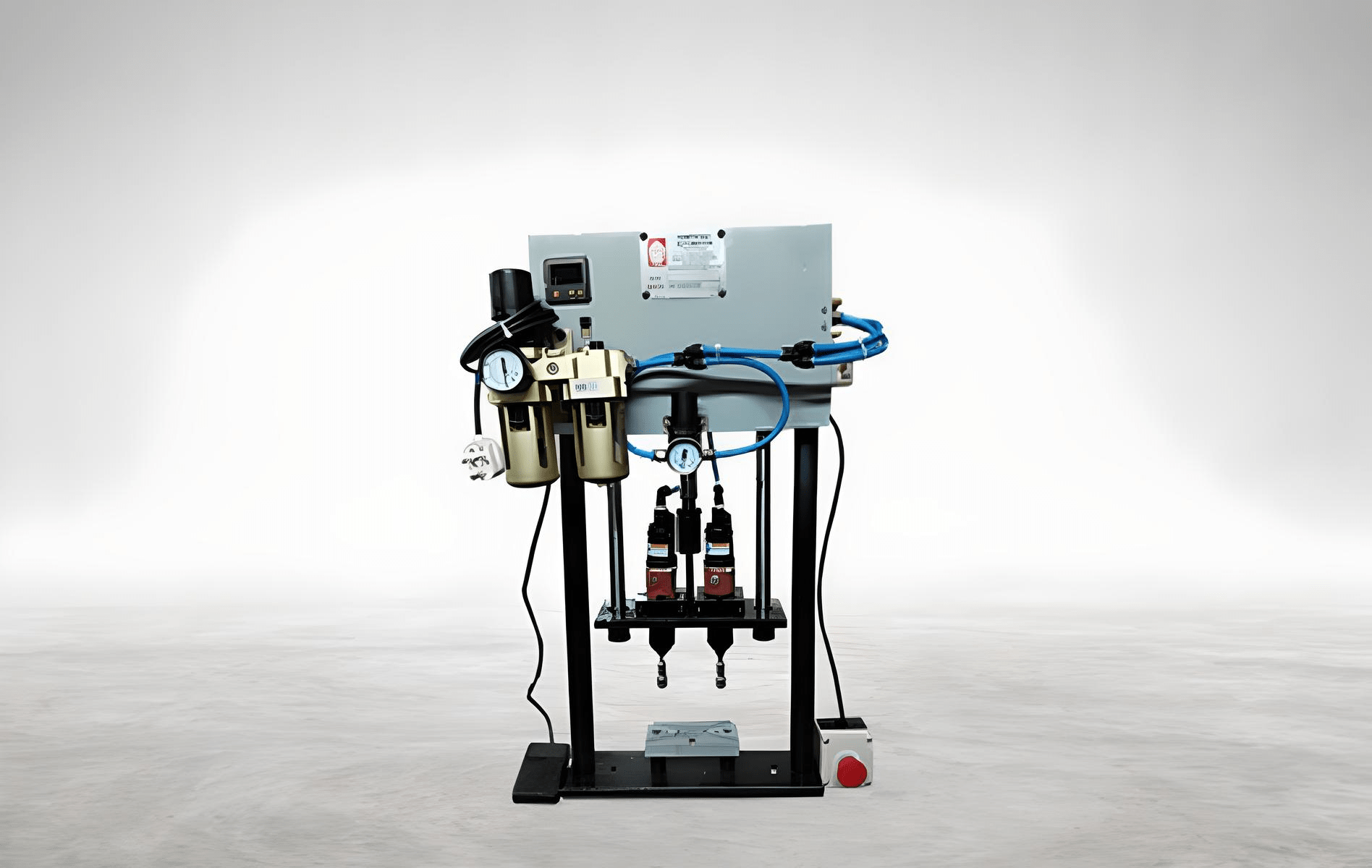

Kamtronix Automation shines as a beacon of innovation and reliability, particularly in the domain of pneumatic presses. Renowned as a leading manufacturer of pneumatic press solutions, Kamtronix Automation has carved a niche for itself by delivering high-quality, precision-engineered equipment that meets the diverse needs of modern manufacturing.

Pneumatic presses play a crucial role in various industries, from automotive and electronics to aerospace and consumer goods.

Completed Projects

Happy Clients

Projects Design

Projects Machinery

SPMs or Special Purpose Machines offer tremendous scope for high volume production at low investment and at low cost of production when compared to CNC machines. SPM, Special Purpose Machines is a high productivity machine, with specially designed tooling and fixture, dedicated for mass producing the same component day in and day out. A judicious combination of limit switches, sensors, logic controls, automatic job clamping etc is the essence of a SPM. A well conceived Special Purpose Machine finds ways and means to utilize the man and machine to the optimum.

Special Purpose Machines (SPM) are uniquely designed to perform particular operations that are not achievable with standard machines. These machines are custom-built to meet the specific requirements of industries, leading to increased production efficiency and precision. By automating repetitive tasks, SPMs reduce the need for manual intervention, thereby minimizing human error and labor costs.

These machines are engineered and designed to meet a specific requirement or process, whic

SPMs are known to deliver extremely high precision and accuracies in their specific applications.

An SPM eliminates the need for manual intervention and human errors, thereby facilitating continuous production at high speeds.

Pellentesque habitant morbi tristique senectus et netus pellentesque neolitics.

Pellentesque habitant morbi tristique senectus et netus pellentesque neolitics.

Pellentesque habitant morbi tristique senectus et netus pellentesque neolitics.

Kamtronix Automation understands our industry's unique requirements and always delivers tailor-made solutions that exceed our expectations. Their expertise and professionalism are truly commendable.

-Nazir Pathan

Kamtronix Automation has been instrumental in streamlining our manufacturing processes. Their SPM machines have significantly increased our productivity, allowing us to meet deadlines with ease.

-Dheeraj Saxena

Thanks to Kamtronix Automation, we've been able to achieve new levels of efficiency in our production line. Their SPM machines are reliable, easy to use, and have helped us reduce downtime significantly.

-Rohit Dhondhiyal